Hot running problems in collector cars with non-cross flow cylinder heads

1955 MGTF Modernization

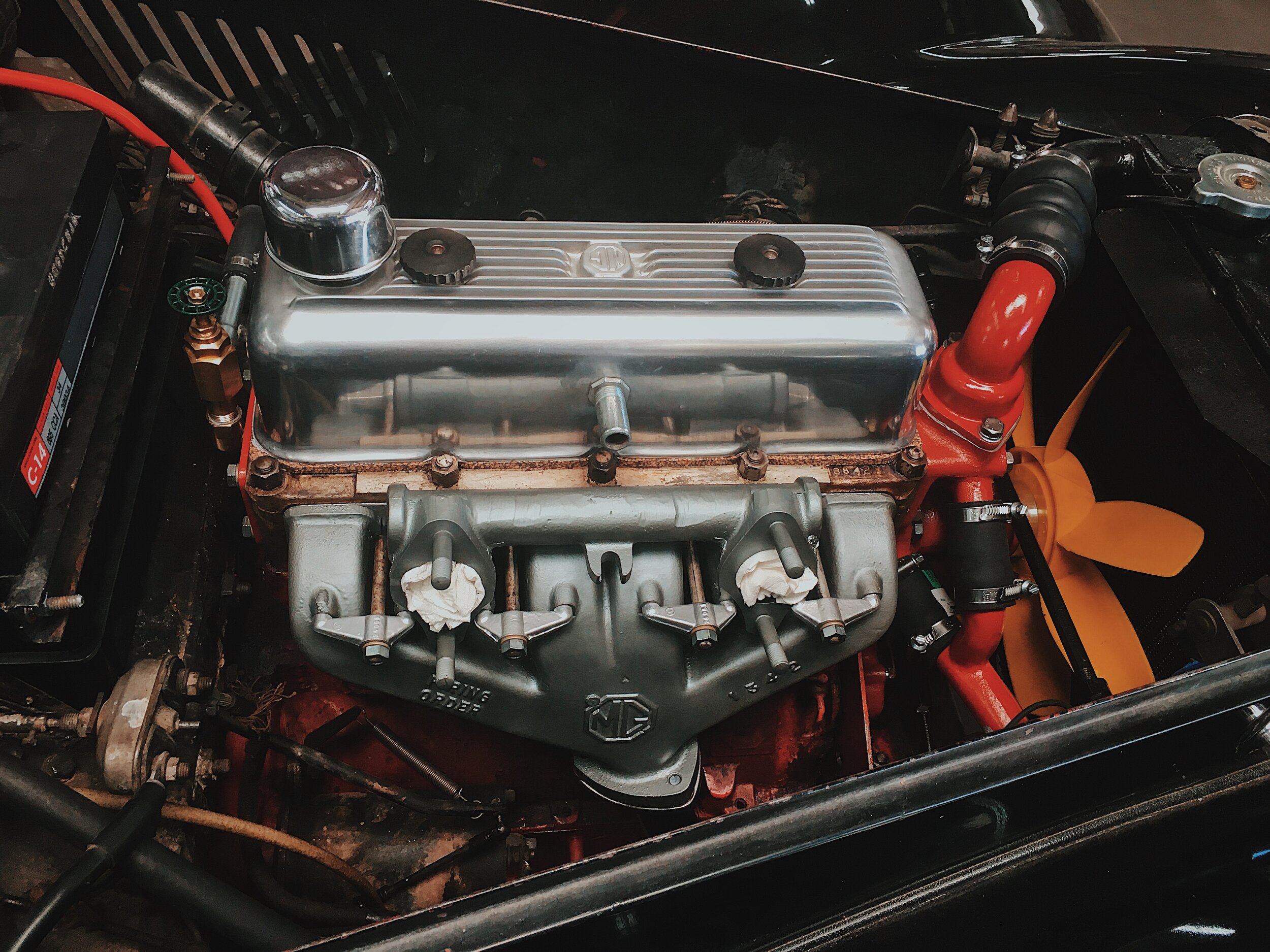

This is a photo of the engine on a 1955 MGTF. The TF was only made for 2 years as a stop-gap before the MGA was developed. We are making it useful on warm/hot days at high altitude. The combination of Ethanol fuel & high altitude creates all kinds of running problems. What happens is the fuel boils in the carburetor float bowls (at a much lower temperature because of the ethanol in the fuel & the altitude) and then float control is lost & there is no longer any fuel mixture control.

What we do to ameliorate the situation is illustrated in the photo. We have a thermal barrier installed on the exhaust manifold & intake manifold. Typically just the exhaust system is done but in this case, the intake manifold is also cast iron (typically they are made of aluminum) so we did both. The thermal barrier reduces radiated heat by about 50%.

Having more air movement in the engine compartment helps the engine run cooler & the fuel system stays cooler. We machined a centering hub for the cooling fan & replaced the 4 blade metal fan (which moves about as much air as asthmatic wheezing through a straw).

Four blade fans are also prone to metal fatigue, breaking apart & causing a lot of damage. They also take much more horsepower to drive than the corresponding multi-blade plastic fan which we source from an MGB.